Ọnụ ahịa N'ogbe Akpaaka Akpaaka Hopper Feeder Scale Jiri maka Osisi ntụ ntụ kemịkalụ

"Dabere na ụlọ ahịa na ịgbasa esenidụt azụmahịa" is our enhancement strategy for Wholesale Price Automatic Weighing Hopper Feeder Scale Use for Chemical Powder Plant, Incouraged via the fast producing marketplace of your fastly food stuff and drink consumables all around the world , We have nọ na-atụ anya ịrụ ọrụ na ndị mmekọ / ndị ahịa iji nyere aka mee mmezu n'etiti ibe ha.

"Dabere na ahịa ụlọ ma gbasaa azụmahịa nke mba ofesi" bụ atụmatụ nkwalite anyị makaỌkọlọgụ na nha nri nke China Hopper, Anyị ugbu a nwere elu mmepụta technology, na-achụ ọhụrụ na ngwaahịa.N'otu oge ahụ, ezi ọrụ emewo ka aha ọma dịkwuo elu.Anyị kwenyere na ọ bụrụhaala na ị ghọtara ngwaahịa anyị, ịkwesịrị ịdị njikere ịghọ ndị mmekọ na anyị.Na-atụ anya ajụjụ gị.

Vidiyo

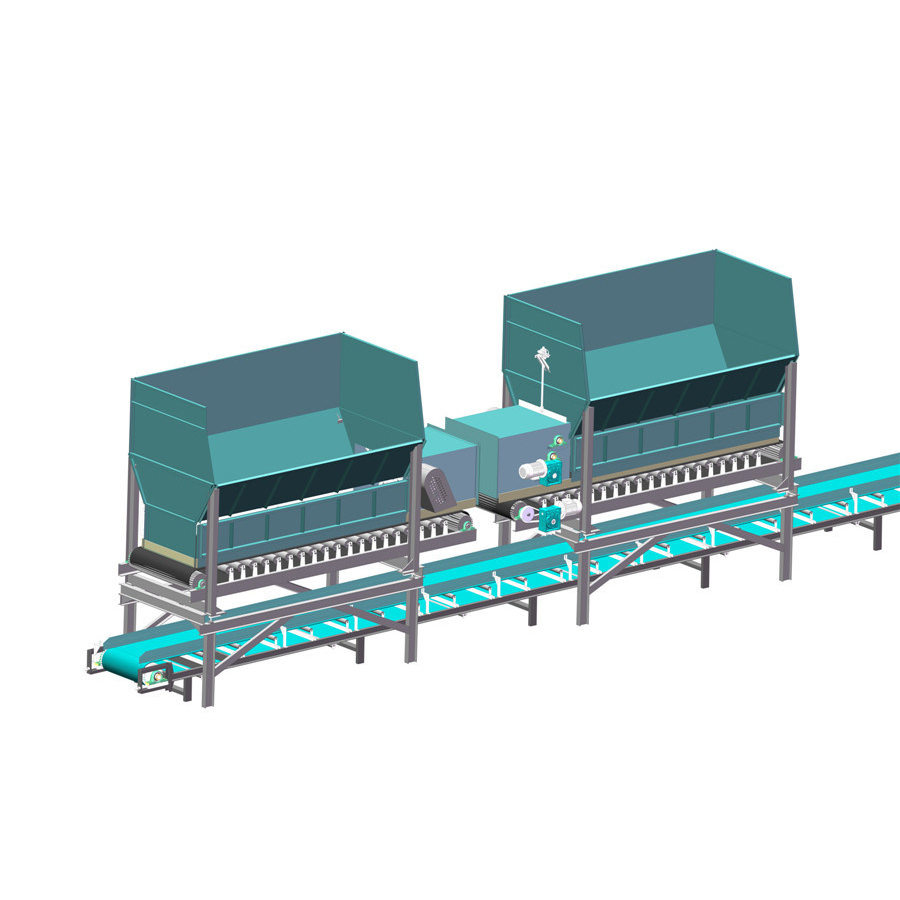

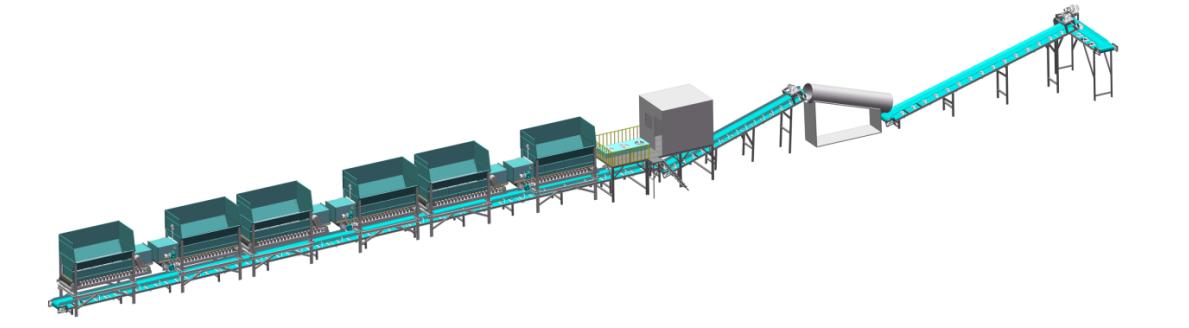

Nkọwa nke ọnụ ọgụgụ nri Hopper

Na-ewebata ọkwa nri hopper ọhụrụ, mgbakwunye kachasị ọhụrụ na ahịrị ngwaahịa anyị!

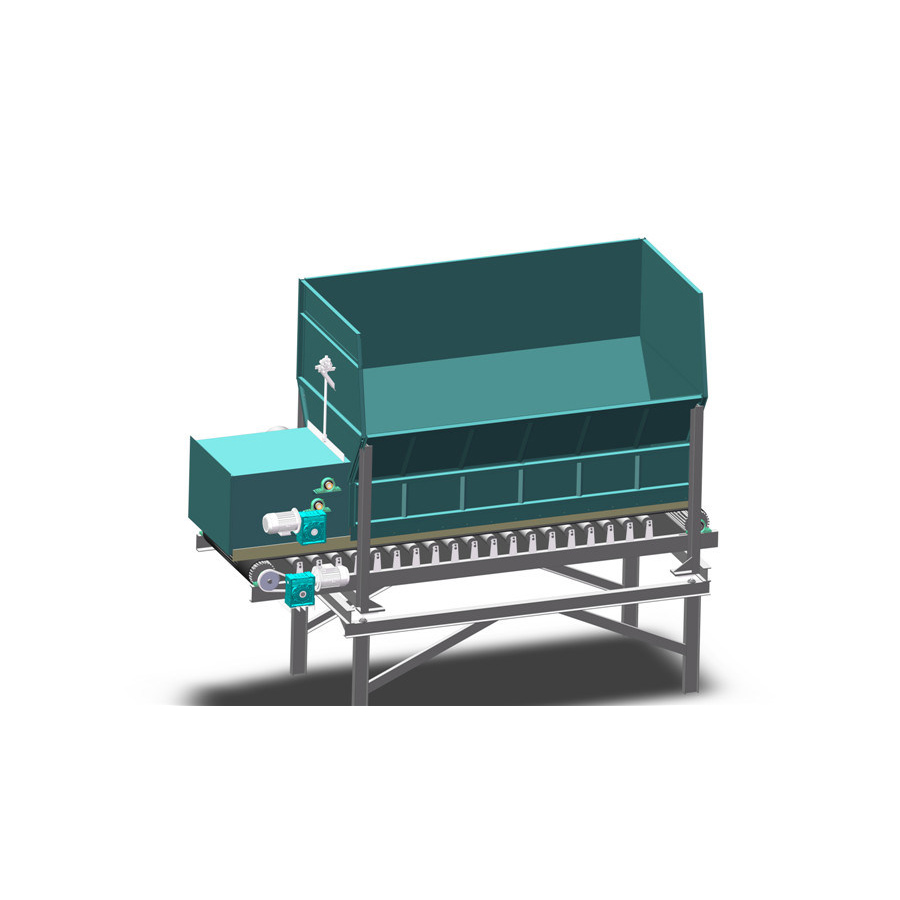

Emebere ọnụ ọgụgụ nri hopper anyị nke ọma na ịdị mma n'uche, ọkachasị maka ụlọ ọrụ dịka ọrụ ugbo, mmepụta nri na nhazi kemịkal.Ọnụ ọgụgụ ahụ nwere ike ịtụ n'ụzọ ziri ezi ma kesaa ụdị ihe dị iche iche, sitere na ntụ ntụ na granules ruo mkpụrụ na mmiri mmiri.

Otu n'ime njirimara dị mkpa nke ọnụ ọgụgụ nri hopper anyị bụ nnukwu ikike hopper, nke na-enyere ndị ọrụ aka itinye ọnụ ọgụgụ buru ibu n'otu oge, na-ebelata mkpa maka ịmegharị ugboro ugboro na imeziwanye arụmọrụ ọrụ.Emebere hopper ka ọ bụrụ uzuzu, na-ahụ na ihe a na-atụle na-anọgide na-adị ọcha na ịdị ọcha n'oge usoro a.

Ntụnye ziri ezi na nke a pụrụ ịdabere na ya dị mkpa n'ọtụtụ ụlọ ọrụ, ọnụ ọgụgụ nri anyị na-enye hopper na-enye nnọọ nke ahụ.Ejiri ya na mkpụrụ ndụ ibu dị elu dị elu, na-enye ohere maka ịgụ ihe ziri ezi ọbụna na ihe dị iche iche dị iche iche.Ọkwa nnabata nke ọnụ ọgụgụ ahụ bụ nke a na-agbanwe agbanwe, na-eme ka ọ dị mma maka iji ihe nwere njupụta dị iche iche ma ọ bụ njirimara eruba.

Na mgbakwunye na izi ezi ya, ọnụ ọgụgụ nri hopper anyị dịkwa mma nke ọma ma dịkwa mfe iji rụọ ọrụ.Ọ na-abịa onwem na onye ọrụ-enyi na enyi akara panel na ihe kensinammuo interface na-enye ohere ọrụ jikwaa ọnụ ọgụgụ si ntọala na ọrụ na ala.Ọnụ ọgụgụ ahụ na-egosipụta mwepu ihe na-akpaghị aka, na-ewepụ mkpa ọ dị maka ntinye aka na nhazi usoro nhazi.

Ọzọkwa, a haziri ọnụ ọgụgụ nri hopper anyị site n'uche ogologo ndụ na ogologo ndụ.A na-emepụta ya site na ihe ndị dị elu, na-ahụ na ọ nwere ike iguzogide iji ya eme ihe ugboro ugboro na ikpughe ọnọdụ ndị siri ike.Ọnụ ọgụgụ ahụ na-egosipụtakwa mkpuchi mgbochi corrosion dị elu, nke na-echebe megide mmiri na mmebi corrosion, na-eme ka ndụ dịkwuo ogologo.

Ọdịiche dị iche iche nke nri nri hopper na-eme ka ọ dị mma maka ojiji n'ọtụtụ ụlọ ọrụ, gụnyere Ngwuputa, kemịkalụ, na ụlọ ọrụ ọgwụ, n'etiti ndị ọzọ.Enwere ike ịhazi ya ka ọ dabara na ngwa ngwa achọrọ, ọ nwekwara ike ijikwa ọrụ mmepụta obere na nnukwu.

Ọnụ ọgụgụ nri hopper na-abịa na nkwado ndị ahịa raara onwe ya nye, akwụkwọ ntuziaka onye ọrụ zuru oke, na ihe ọzụzụ, na-ahụ na ndị ọrụ niile nwere ike iji ikike ya mee ihe nke ọma.

Ọnụ ọgụgụ nri anyị hopper bụ ihe ọhụrụ na nke a pụrụ ịdabere na ya emebere maka ịtụ na ikesa ọtụtụ ihe.Izi ezi ya, ịdịte aka na ịdị mfe nke iji ya na-eme ka ọ bụrụ mgbakwunye dị mma na usoro mmepụta ọ bụla, na-emeziwanye arụmọrụ, yana ibelata ọnụ ahịa.Kpọtụrụ anyị taa ka ịmatakwu ka ngwaahịa anyị nwere ike isi gbanwee ọrụ gị!

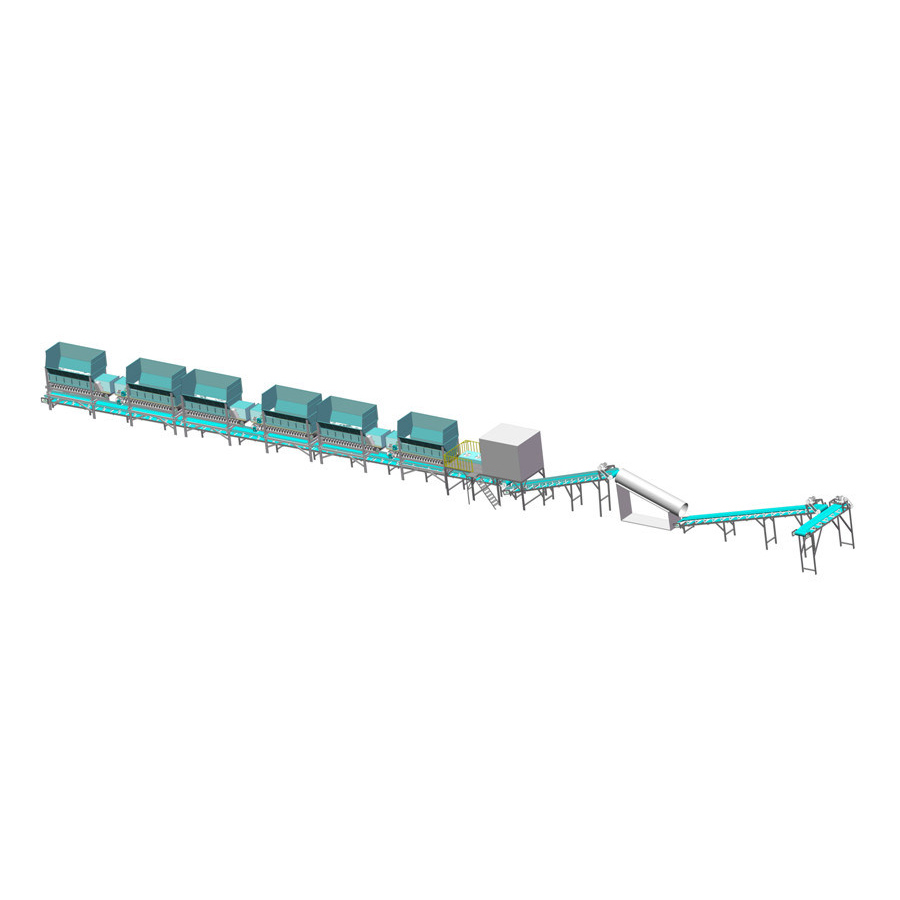

Sistemụ batching ọgụgụ isi na-arụ ọrụ

1. Usoro batching nke Wang Gong Weighing feeder nwere ike izute mkpa batching nke ụdị mmepụta ihe dị iche iche, ma nwee ike ịhazi ya na ọtụtụ feeders, nke dị mfe ịmalite, arụmọrụ dị elu, mmepụta dị elu, na ihe dị mma.

2.Adopt ihuenyo ihuenyo mmetụ na njikwa ọrụ bọtịnụ.A na-egosipụta ịdị arọ ihe dị adị na ọnọdụ ọrụ nke onye na-enye nri ọ bụla na ihuenyo mmetụ ozugbo, yana ọnọdụ ọrụ nke ebufe ọ bụla.Ọnụ ego e lekwasịrị anya nke ihe usoro ahọpụtara, iru mmiri ( iru mmiri nwere ike gbanwee), oke oke oge.

3.The nri usoro akara mode na-ekewa n'ime zuru akpaka mode na ntuziaka mode

4. Ihuenyo dijitalụ na-egosiputa ịdị arọ nke ihe dị na feeder ozugbo, na oge nkwụsị nke usoro okirikiri na ọnọdụ akpaka na-egosipụta site na ngụgụ nke ihuenyo dijitalụ.Ngosipụta ihuenyo dijitalụ “——-” mgbe feeder adịghị mkpa ịrụ ọrụ nhazi.

5.Conveyor njikwa: Mgbe onye na-ebufe ihe na-enye nri na-akpaghị aka, mgbe onye na-eri nri gụchara nri n'otu oge, onye na-ebufe ihe kwesịrị igbu oge nnyefe nke ihe ndị na-ebufe ihe na ụlọ ngwakọta.

6.The feeder na-onwem na infrared grating, na forklift loading emetụ grating akara mgbe akpaka mode na-azụ, na dum akara na-aga n'ihu na-akpaghị aka mgbe loader na-apụ mgbe loading.

7.Na-enye mmepụta mgbanwe na mmalite nke batching na ntụgharị ntụgharị na njedebe nke batching

8.Mgbe onye na-enye nri dị ala karịa ụfọdụ arọ, ahịrị ahụ dum na-akwụsị nri na-akpaghị aka ma na-eti mkpu site na ọkụ ọkụ.

9.Formula nchekwa 10, data nri na-edobe ma ọ dịkarịa ala otu ọnwa, nkwụsị ọkụ na mmejọ na-edekọ ibu nke nri.

Uru Sistemu

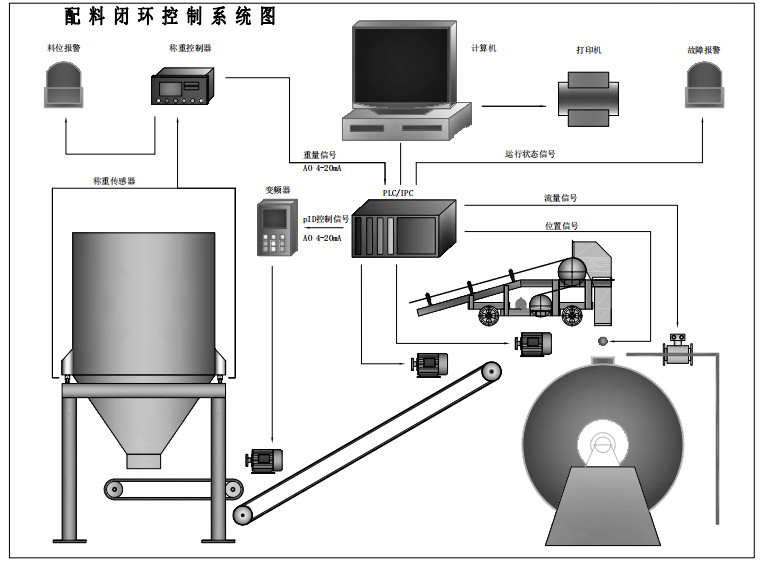

1: Sistemụ batching akpaka na-anabata onye na-ahụ maka mmemme na kọmpụta mmepụta ihe dị ka isi, nke pere mpe, dị elu na nkenke yana ezigbo nkwụsi ike.

2: Usoro batching akpaaka nwere ike ijikwa ọtụtụ akpịrịkpa, ihe dị iche iche dị iche iche ma ọ bụ mmepụta njikwa n'otu oge (dabere na usoro)

3: njikwa ọgụgụ isi nke oge batching, ọ dịghị echere n'etiti akpịrịkpa ihe, nke mere na okirikiri batching na-ebelata, melite ọsọ ọsọ na mmepụta.

4: The akpaka batching usoro adopts ọhụrụ usoro ikpo okwu, nke na-agba ọsọ ngwa ngwa na ọzọ kwụsie ike, ezigbo oge ike mmepụta ihuenyo, na-egosi mmepụta usoro, kensinammuo ọrụ, doro anya na akpaka mgbake ọrụ.

5: Sistemụ batching akpaka nwere ọrụ akụkọ siri ike, nwere ike ịdekọ ma chekwaa ụdị data dị iche iche na mbipụta tebụl n'ọtụtụ buru ibu, na-achịkọta ma bipụta akụkọ ihe na-akpaghị aka mgbe emechara mmepụta ọ bụla, wee nye ụbọchị, oge, nọmba akụkọ na nke ahụ n'ezie. oriri nke ihe ọ bụla;Mwepụta akụkọ ahụ na-agbaso usoro ajụjụ akwụkwọ ntuziaka PC, na-echekwa akụkọ njedebe mmepụta n'ime kọmputa, nke enwere ike ịgụ ya ruo mgbe ebighị ebi iji hụ na izi ezi na iguzosi ike n'ezi ihe nke akụkọ mmepụta.

6: Ọrụ dị mfe, usoro ahụ nwere akwụkwọ ntuziaka, ọkara akpaaka, ụdị mmepụta atọ zuru oke.

7: Ike nhazi data siri ike, ọnụego nlele ngwa ngwa ma kwụsie ike, usoro batching nwere ike izute usoro chọrọ nke batching.

8: The akpaka batching usoro usoro nwere ike ịtọ dị ka onye ọrụ.

9: ezigbo ntụkwasị obi, sistemu batching akpaka nwere atụmatụ njikwa abụọ (ihuenyo mmetụ na mmemme kọmputa mmepụta ihe) Mgbe otu n'ime ụdị ndị mba ọzọ nwere mmejọ, nke ọzọ na-ebipụ ozugbo n'ime ọrụ na-enweghị emetụta mmepụta, na sistemụ batching akpaka nwere ike iwepụ mmepụta runaway phenomen mgbe mmepụta ọdịda emee.

10: Usoro batching akpaka na-egosiputa usoro mmepụta ihe na oge na ederede na-egosipụta usoro mmepụta, nke dị mma maka onye ọrụ na-arụ ọrụ.

11: Akpaaka batching faịlụ faịlụ ederede na-egosiputa akụkọ mmepụta, akụkọ nhazi, wdg (enwere ọtụtụ ọdịnaya ebipụtara nke onye ọrụ ahọrọ) Ọrụ mgbanaka siri ike, nke nwere ike ibelata ọnụego nkwụsịtụ na opekempe.

12: Usoro nhazi nke akpaaka na-akpaghị aka, oge ntọhapụ nke ọ bụla na-eji ihe ntụgharị ugboro ugboro iji chịkwaa ọsọ ọsọ ka onye ọ bụla na-agbakọta n'otu oge iji hapụ ya, iji hụ na ịdị n'otu nke batching.

13: Automatic batching usoro online akpaka nlekota software: mmekọrịta dị n'etiti ndị mmadụ na mmepụta akara si na-agafe agafe na-arụsi ọrụ ike, ozugbo mmepụta nke ndiiche ọnọdụ, kọmputa usoro ozugbo na-ebute ụzọ izipu mkpu na mkpa pesonel, buru ụzọ na- rụọ ọrụ nchetara, site na nleba anya n'ịntanetị n'ezie, nyochaa ozi dị mkpa nke mmepụta n'oge ọ bụla

Kedu ka ihe batching si arụ ọrụ

Dị ka ihe atụ, akpaka batching usoro na-emi esịnede 5 electronic belt ọnụ ọgụgụ batching ahịrị, ọnụ 1#, 2#, 3#, 4#, 5#, nke 1# ~ 4# bụ otu, 1# bụ isi ihe. ọnụ ọgụgụ, na atọ nke fọdụrụ bụ ihe ọ̀tụ̀tụ̀ ihe inyeaka.Mgbe ọ dịghị mkpa ịgbakwunye excipients, 5 # eletrọnịkị ọnụ ọgụgụ na-arụ ọrụ naanị iji nyefee isi ihe.Usoro nwere ọrụ abụọ: na-agba ọsọ mgbe niile na njikwa oke.Maka njikwa mmiri na-agba ọsọ mgbe niile, eriri eletrọnịkị na-emezi ọsọ nke eriri ahụ na-akpaghị aka dabere na ọnụọgụ nke ihe dị na eriri ahụ iji zute ihe achọrọ eruba.A na-enyocha usoro nrịbama nke usoro isi (1 #), ma gosipụta usoro usoro ahụ na foto 1.

Mgbe agbanyere sistemu batching akpaka, moto belt na-amalite ịtụgharị, microprocessor na-ejikwa ọsọ moto dị ka ọrụ dị ugbu a si dị.Ihe dị na hopper na-adaba na mpaghara oghere ma na-ebuga ya site na eriri na ebe a na-atụ aro, ebe a na-eji eriri eletrọnịkị tụọ ihe dị na eriri ahụ.Igwe ibu ahụ na-ewepụta mgbama voltaji dabere na ịdị ukwuu nke ike, nke na-ebuwanye ibu site na nnyefe ka ọ wepụta akara ọkwa ọkwa nha nha nha nke ihe ahụ.A na-eziga mgbama ahụ na interface nke kọmputa onye ọbịa, na-enyocha ma gbanwee ka ọ bụrụ akara okporo ụzọ, na-egosipụta uru eruba ugbu a na kọmputa onye ọbịa.N'otu oge ahụ, a na-eziga mgbaàmà mgbaba a na interface PLC, ma e jiri ya tụnyere ihe dị iche iche nke kọmpụta onye na-elekọta ya, wee rụọ ọrụ nhazi ahụ, a na-ezigakwa ego njikwa na ntụgharị ugboro ugboro iji gbanwee uru mmepụta nke. ihe ntụgharị ugboro ugboro, si otú ahụ na-agbanwe ọsọ nke moto ịnya ụgbọ ala.Gbanwee dosing ka ọ hà nhata ahazi iji mezue usoro batching akpaka.

Ntọala paramita

| Chepụta ike batching | 0 ~ 120t / h |

| Guzosie ike na-atụle izi ezi | 1/1000 |

| Izi ezi usoro batching | 2/1000 |

| Nhazi mmezi dabara adaba | 1/1000 |

| Nha urughuru ihe | ≤100mm (ogologo diagonal kacha) |

| Mmiri ọdịnaya nke ihe onwunwe | ≤10% |

| Ụdị njikwa sistemụ | Centralized, njikwa n'ime ebe |

| Jiri okpomọkụ gburugburu | -10℃~+45℃ |

| Jiri iru iru mmiri | ≤90% RH |

| Sistemụ grid voltaji | 380V± 10%220V±10%;50Hz |

| Ike eletriki | ≤200kw |

| Usoro ọrụ usoro | Na-aga n'ihu |

Ahịa chọrọ

Efrata bụ usoro dị oke mkpa na usoro mmepụta nke ụlọ ọrụ mmepụta ihe, àgwà, arụmọrụ na nkwụsi ike nke usoro batching na-arụ ọrụ dị mkpa na usoro mmepụta mmepụta ihe dum na àgwà nke ngwaahịa ahụ, usoro ihe na-azụ azụ abụghị nanị na-adịghị arụ ọrụ na na-ezighị ezi, akwụkwọ ntuziaka ọrụ nke Efrata na iwebata ihe ndị mmadụ n'ime njikọ batching, nke na-emetụta nkwụsi ike na nkwụsi ike n'ihu nke àgwà ngwaahịa, ma nwee nnukwu ọrụ ike, enweghị nchebe ọrụ, nchebe gburugburu ebe obibi erughị ụkpụrụ na ntụpọ ndị ọzọ. , Ihe eji eme ihe na-eme ka o sie ike ịmepụta mmepụta ihe mmepụta ihe na nnukwu mmepụta mmepụta ihe.Ya mere, usoro batching dị elu na nke nwere ọgụgụ isi dị oke mkpa maka ụlọ ọrụ mmepụta ihe.

The mkpa ọrụ nke China si ngwa ngwa na-eto eto "ụwa n'ichepụta osisi" na dịtụ azụ ulo oru nwere ọgụgụ isi batching usoro ụlọ ọrụ etolitela nnukwu esemokwu na ahịa ohere, na-eme ka anụ ụlọ nwere ọgụgụ isi batching usoro ahịa a zuru ụwa ọnụ ahịa ahịa, ma na-adọta anụ ụlọ inflows, nwere. ụbara ego na ulo oru nwere ọgụgụ isi Efrata ụlọ ọrụ, na-arụsi ọrụ ike meghere ụlọ ahịa.

A na-eji teknụzụ njikwa ọgụgụ isi dị ka teknụzụ njikwa eletriki, teknụzụ nha, teknụzụ nhụta, teknụzụ ngwanrọ kọmputa, teknụzụ igwe, ihe na teknụzụ kemịkalụ na teknụzụ ndị ọzọ dị iche iche, teknụzụ ọkachamara nwere ihu dị iche iche, teknụzụ njikwa ọgụgụ isi na-ejikarị na ụlọ ọrụ mmepụta ụlọ ọrụ mmepụta ihe akụrụngwa, nha ihe inyeaka, njem, nchekwa na nri na akụkụ ndị ọzọ nke njikọ ahụ.

Ngwa ikpe

"Dabere na ụlọ ahịa na ịgbasa esenidụt azụmahịa" is our enhancement strategy for Wholesale Price Automatic Weighing Hopper Feeder Scale Use for Chemical Powder Plant, Incouraged via the fast producing marketplace of your fastly food stuff and drink consumables all around the world , We have nọ na-atụ anya ịrụ ọrụ na ndị mmekọ / ndị ahịa iji nyere aka mee mmezu n'etiti ibe ha.

Ọnụ ahịa n'ogbeỌkọlọgụ na nha nri nke China Hopper, Anyị ugbu a nwere elu mmepụta technology, na-achụ ọhụrụ na ngwaahịa.N'otu oge ahụ, ezi ọrụ emewo ka aha ọma dịkwuo elu.Anyị kwenyere na ọ bụrụhaala na ị ghọtara ngwaahịa anyị, ịkwesịrị ịdị njikere ịghọ ndị mmekọ na anyị.Na-atụ anya ajụjụ gị.

Ụdị ngwaahịa

-

Ekwentị

-

E-mail

-

WhatsApp

-

WeChat